Hot filament chemical vapor deposition (HFCVD) has many advantages such as mature technology and simple equipment. It is one of the most widely used methods for preparing diamond thin films in industry. Designed for the synthesis of nanodiamond coatings, CVD diamond films, microcrystalline CVD diamond coatings, graphene, carbon nanotubes (CNTs) and various other thin film coatings. As the hardest substance in all known materials, diamond also has high thermal conductivity, high elastic modulus, good wear resistance, corrosion resistance, low friction coefficient and chemical stability, and is an excellent material for cutting. The equipment includes a reaction chamber, a support system, a water system, a gas system, and an automatic control system. The equipment is compact in structure and reasonable in layout. After years of equipment research and development by the engineer team, repeated deliberation, many experiments, combined with the computer-aided design system, have been checked and verified countless times. The equipment has excellent deposition performance and reliable safety. This product is an excellent device integrating energy saving, reliability, convenience and intelligence.

HFCVD Product features:

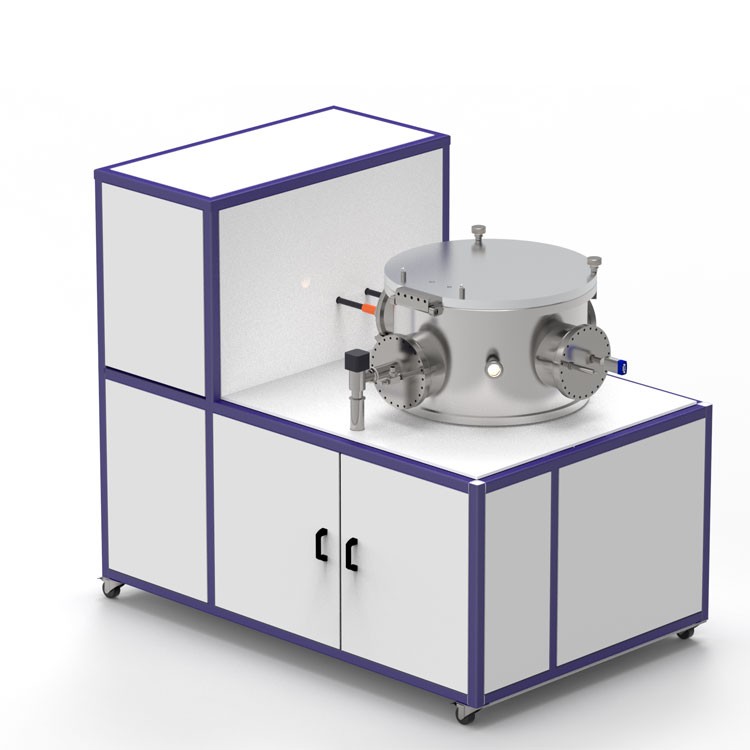

This product is a double-layer stainless steel cavity structure, with a compact and reasonable structure;

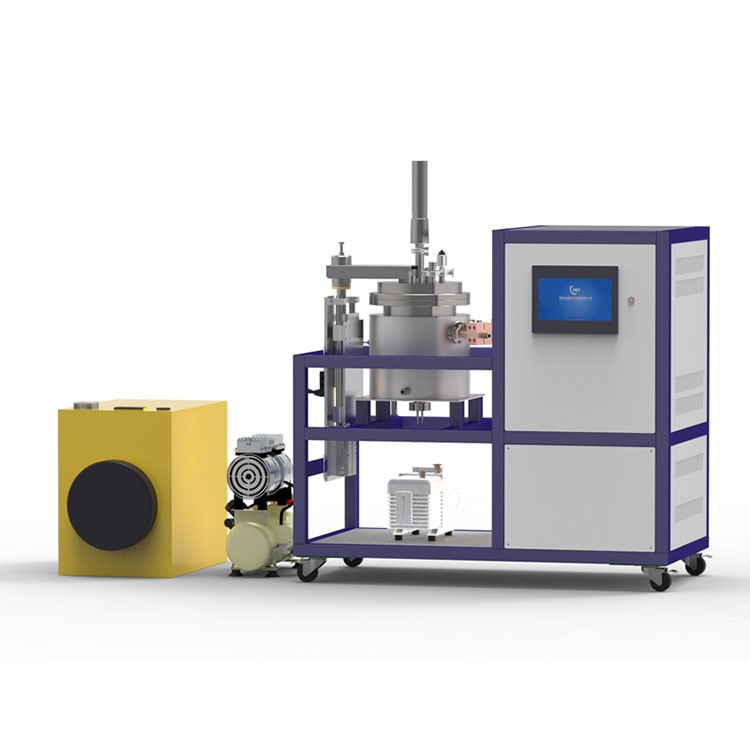

This product is divided into two parts: the upper stage and the lower stage. In addition to supporting the reaction chamber, the lower stage is also used to arrange gas valve, water pipeline and various control components. Arrange display panels and power supply devices on the bench to reasonably shield circuit interference;

This product fully disperses the cooling water channel layout (the upper cover of the cavity, the upper and lower layers of the cavity body and the bottom plate, as well as the hot wire elastic device, etc.). Water pumps, water pipes, intelligent monitoring flow meters, water manifolds, etc. are all closed circulation systems.

The gas circuit combination of this product is mainly composed of process gas supply system and vacuum system, reasonable distribution of gas pipelines, effective use of available space, real-time monitoring and precise control of gas flow and pressure.

This product uses a two-stage chip vacuum pump, and the pumping speed is stable at 65m3/h. The ultimate absolute vacuum full pressure is 0.5Pa, and the protection level is IP54.

HFCVD Technical indicators and characteristics:

Vacuum chamber | Structure: cylindrical + upper cover Material: 304 high-quality stainless steel Cavity size:Φ640x320mm |

Power supply: | AC220V / Three-phase 380V 30KW |

Temperature control | Low voltage and high current DC power supply with hot wire temperature up to 2500°C. Deposition substrate surface: about 600℃ Cavity wall temperature: <60℃ Temperature control accuracy: 0.1℃ |

Temperature measurement system | Far infrared optical temperature measurement + thermocouple monitoring |

Hot wire device: | Constant tension array geometry, molybdenum wire, copper feedthrough, tungsten wire bond processing for easy adjustment and maintenance |

Observation window | Main observation window φ190mm Auxiliary observation window φ45mm |

Water system | Water-cooled electrode, water-cooled cavity, water-cooled heating wire auxiliary components Main water pipe interface size 40mm Cooling water flow: 60L/MIN |

Vacuum system | Two-stage rotary vane pump + high vacuum valve combination (safety valve, flow sensor, regulating valve...), digital display composite vacuum gauge, Maximum pumping speed: 65 m3/h Equipment pressure maintenance: 12 hours after the pump is stopped, the vacuum is less than or equal to 10Pa; Exhaust port CF40 Exhaust port KF16 |

Operating system: | PLC+touch screen man-machine interface semi-automatic control system; |

Security system | Alarm and protection: alarm and implement corresponding protection measures for abnormal conditions such as water shortage, overcurrent and overvoltage, and open circuit of pumps and electrodes; perfect logic program interlock protection system; |

Footprint size | (Host) L1800×W1150×H1550(mm). |

Total Weight | 600kg |